- You are here:

- Homepage

- Events

- UK Roofing Awards

- NFRC UK Roofing Awards 2025—Winners

NFRC UK Roofing Awards 2025—Winners

The winners of the 2025 NFRC UK Roofing Awards were revealed on 9 May at the InterContinental London—The O2. The awards ceremony was hosted by stand-up comedian, actor and presentor, Ed Byrne.

Radmat Building Products were the Headline Sponsor for the event, with Recticel Insulation sponsoring the drinks reception and after party.

Photographs from the day are available to see in the gallery.

Congratulations to all the winners and also to all the shortlisted finalists. A record-breaking number of entries were submitted for the 2025 Awards, showing that the exceptional talent across the industry continues to grow and thrive.

The 2025 awards celebrated roofing and cladding projects completed between 1 January 2024 and 31 December 2024.

Individual awards were also presented to Young Roofer of the Year, Individual Health & Safety Award, Local Hero, Industry Choice (as voted for by the public), and the Project of the Year.

![NFRC Awards [2025] Winner Logo (PNG).png](https://www.nfrc.co.uk/static/88d46b5e-6361-4587-b315854a93865d39/300x337_highestperformance__4a7c7e45a350/NFRC-Awards-2025-Winner-Logo-PNG.png)

Gallery of winners

Download and share these images and tag NFRC using #RA2025

Bituminous Hot Applied Liquid Waterproofing-Lindner Prater Ltd

Cold Applied Liquid Waterproofing-Central Group

Fully Supported Metal-Install Zinc Ltd

Green Roofing-Weatherproofing Advisors Ltd

Heritage-Claude N Smith Ltd

Leadwork-EWN Leadwork Specialists Ltd

Mastic Asphalt-Fraden Contracts Ltd

Multi-Disc-Longworth Building Services Ltd

Rainscreen Façades-Longworth Building Services Ltd

Reinforced Bitumen Membranes-OBR Construction, working with Sika Ltd

Roof Slating-M. Camilleri & Sons Roofing Ltd

Roof Tiling-Complete Waterproofing Services Ltd

Sheeting & Cladding-Lindner Prater Ltd

Single Ply-Mariner Projects Ltd

Small Scale Project-Karl Terry Roofing Contractors Ltd < £25k

Solar-Marley Contract Services

Project of the Year-Lindner Prater

Industry Choice-Fowler McKenzie Ltd

Young Roofer 2025 Jake Harlow, Safeseal Roofing Ltd

Local Hero-Peter Wilson

This award was collected by Mick Catlin on Peter’s behalf.

Health and Safety Award-Owen Griffiths, Hat Roofing Ltd

Winning projects

Scroll through the images below to find out more about the the 2025 winning projects.

Project of the Year: Lindner Prater Ltd | Everton FC

Everton FC’s new 52,000-seater stadium sets a new benchmark in stadia design, construction, and urban regeneration. One of the most striking and complex aspects of the work was the installation of 872 bespoke barrel vault cladding panels. Each panel, crafted from 3mm anodised aluminium with bespoke perforations.

Industry Choice Award: Fowler McKenzie Ltd | Ardgowan Distillery

This challenging project required a consistent eaves height paired with a tapering ridge height, but with the added complexity of a smooth curved eaves detail. The cladding was colour chosen to compliment the natural setting with every outser sheet cut and rolled on site to exacting unique measurements to achive a stunning finish.

Young Roofer of the Year: Jake Harlow | Safeseal Roofing Ltd

At just twenty-three, Jake has already made a significant impact in the industry, demonstrating exceptional technical and leadership skills. He runs his own jobs with a three-man gang and although he specialises in flat roofing, he is currently running a project involving several green roofs. Jake is not only a key player but also a mentor to others. He coaches colleagues and shares his knowledge to help other advance their careers.

Health and Safety Award: Owen Griffiths | HAT Roofing Ltd

Owen always adopts a safety-first approach, ensuring that his team follow the safe system of work which he assists the creation of, with co-ordination with the HSEQ. He has an excellent visual situational awareness and is not afraid to speak up when something is not right.

Local Hero: Peter Wilson | Gable Roofing

Local Hero for their exceptional contribution to our community through 50 years of dedicated leadership in the roofing industry. As the driving force behind Gable, they have not only built a thriving business but also demonstrated an unwavering commitment to supporting local causes and fostering opportunities within the community.

Bituminous Hot Applied Liquid Waterproofing: Lindner Prater Ltd | Google KGX1

This innovative design integrates cascading green terraces with outdoor pathways, blending natural elements with the architectural aesthetics of the workspace, providing employees with an integrated outdoor space for relaxation, exercise, and work.

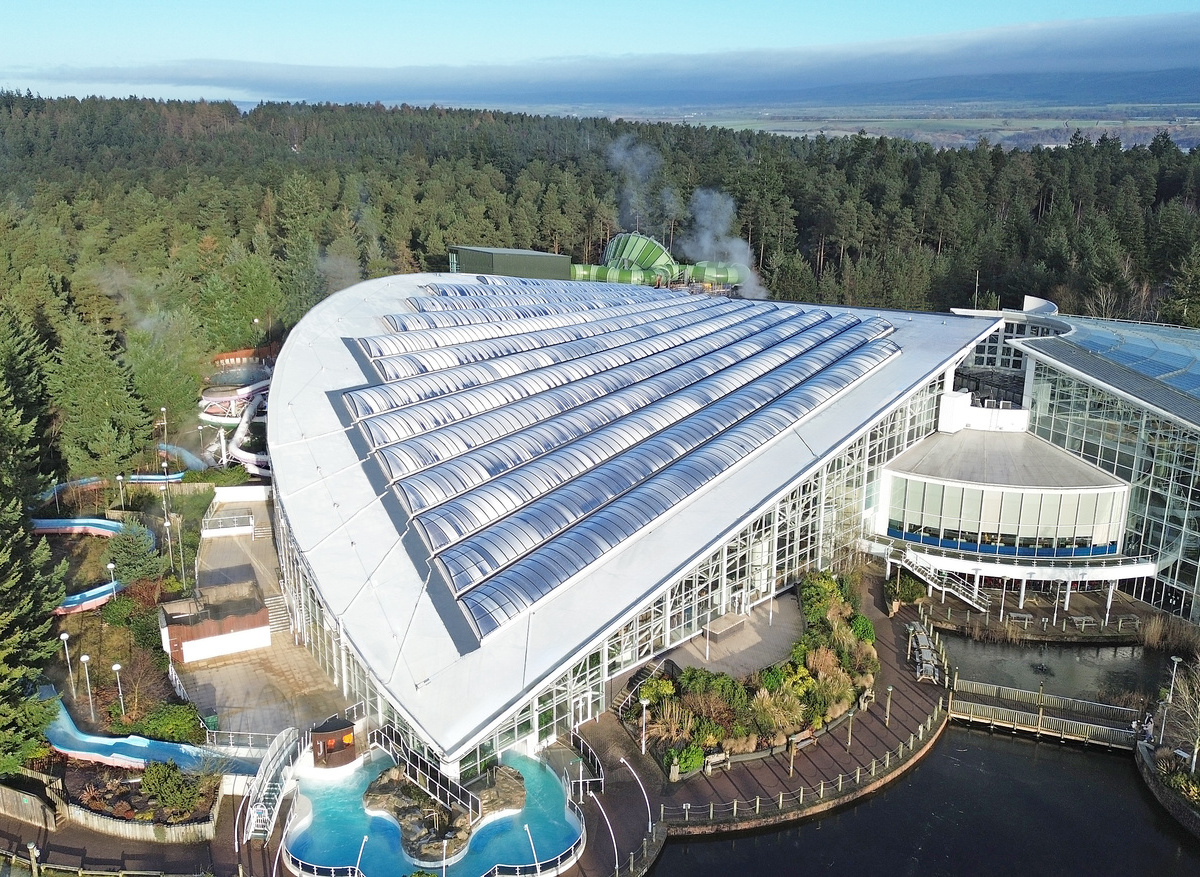

Cold Applied Liquid Waterproofing: Central Group | Whinfell Forest Center Parcs

Re-roofing an occupied swimming pool presenting challenges that required specialist capabilities, effective planning, and execution. Complexities included the operating times of the building, which is accessible to guests 10am to 9pm, and the challenging curved design of the roof, rising from 6m to 27m.

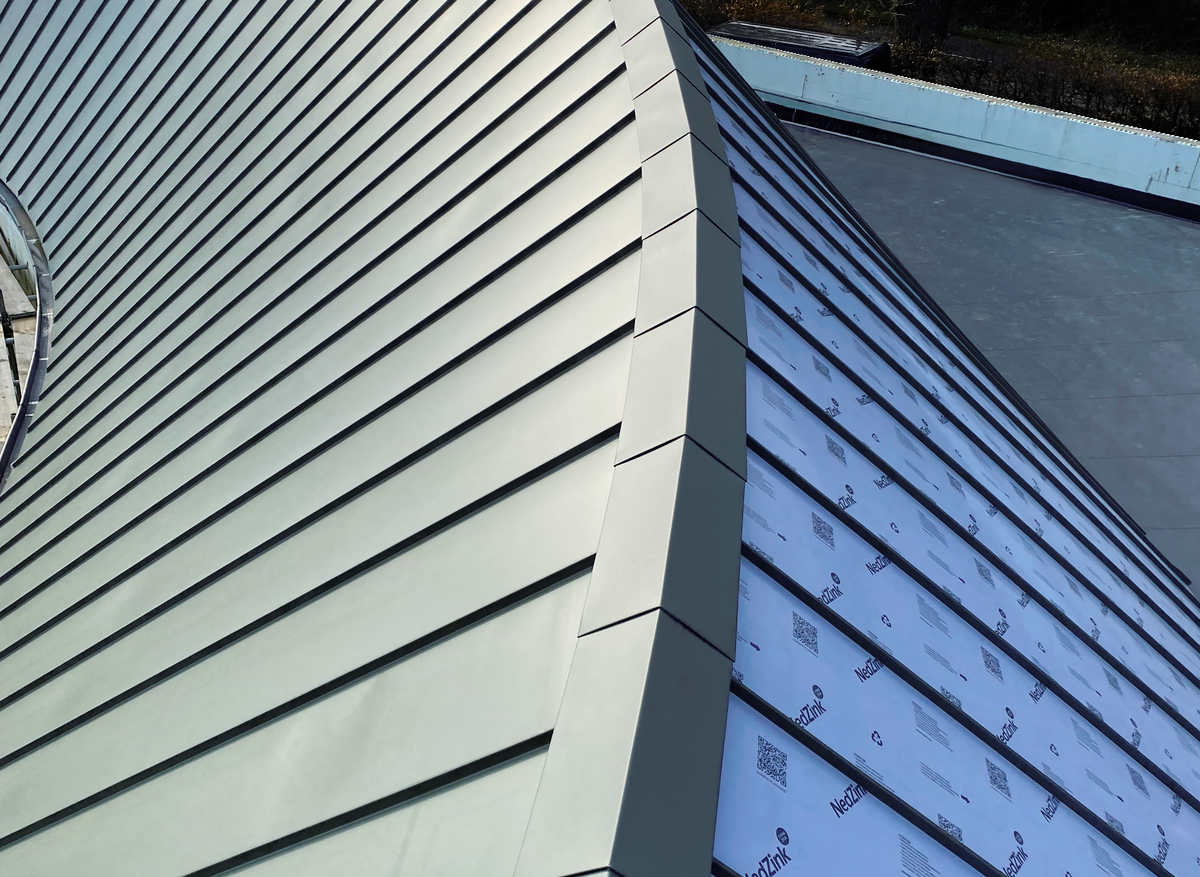

Fully Supported Metal: Install Zinc Ltd | Warrenhurst

Each roof panel was a different size having a different length and different taper due to the curved nature of the roof and the sloping ridge line. The panels were site measured and then fabricated off site to allow for greatest accuracy, in total 146 panels with different lengths and tapered widths were used.

Green Roofing: Weatherproofing Advisors Ltd | Tesco, Weston-super-Mare

Public engagement with the tenants was key, including consultation with residents to ensure that the communal space, offered places for quiet reflection and social interaction. A biodiverse roof was also installed, and included a bug hotel, bee posts and pollinator friendly planting. This project has not only improved the environment in terms of biodiversity net-gain, but provided social value to those that live and work here.

Heritage Roofing: Claude N Smith Ltd | Christ's College Cambridge

This project is the second phase of re-roofing works at the grade 1 listed Old Court at Christ’s College, Cambridge, using Collyweston Slate from the contractor's own mine. The limestone Collyweston slates are laid on the roof in diminishing courses, then bedded with lime mortar.

Leadwork: EWN Leadwork Specialists Ltd | Lloyds Bank, Penzance

This complex project includes four large scrolls. The lower parts were shaped to match the original timber pattern, while the top scrolls featured original spun timber encapsulated in lead. The details on the taurus rolls were intricate, involving two layers and multiple corners.

Mastic Asphalt: Fraden Contracts Ltd | MOD, Shoeburyness

The rock asphalt was re-laid on the prepared deck using traditional spreading and rolling techniques, many of which are lost to a bygone age. The process ensures uniform thickness and even coverage to maintain watertightness and durability, emphasising the longevity of natural materials such as rock asphalt.

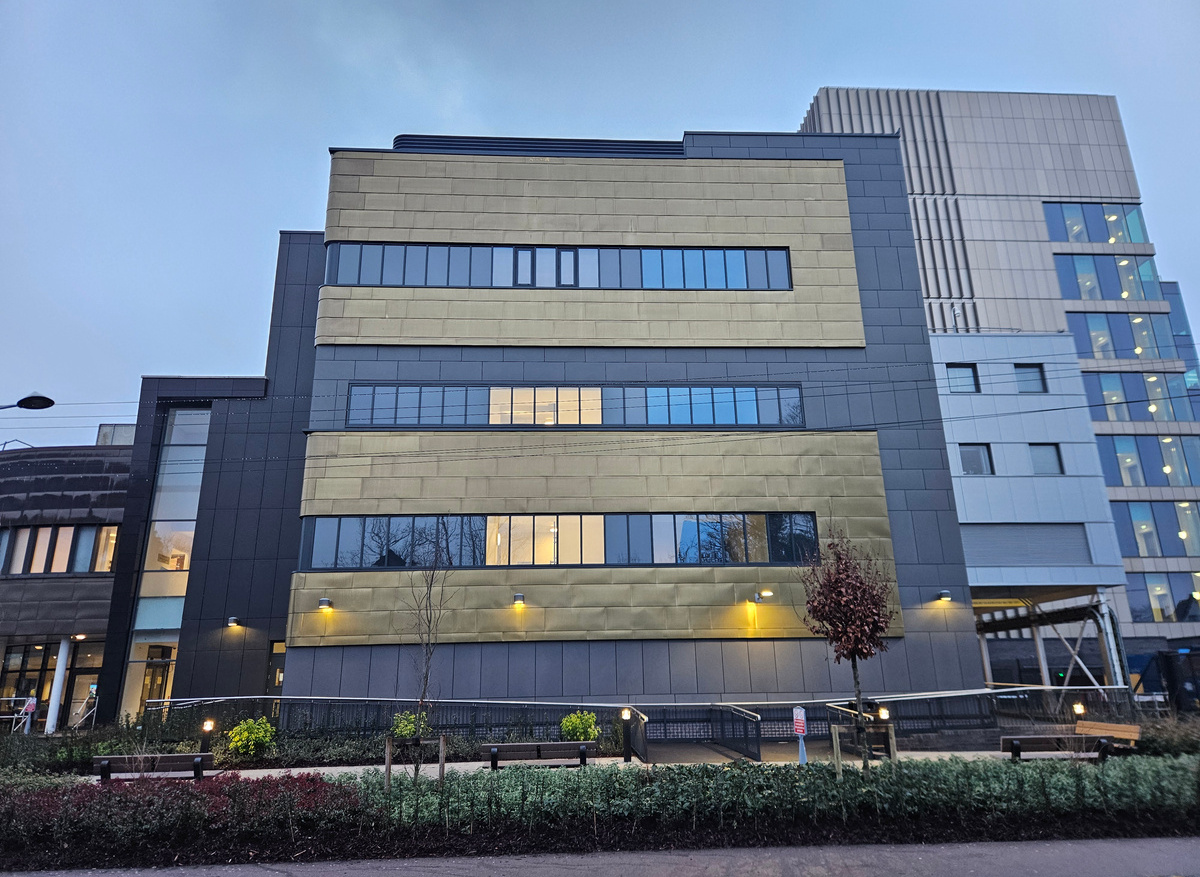

Multi-discipline project > £250k: Longworth Building Services Ltd | TIF Ward, Christie Hospital

This extension included 4 different facade finishes - Tecu Brass, Equitone Natura, Equitone Textura and Eurobond composite panels, each with their own individual detailing challenges and abutments with each other.

Rainscreen Façades: Longworth Building Services Ltd | Stockport Interchange

AlterEgo Limestone and Genius Aluminium rainscreen facades to the Interchange and base the residential block were utilised, including supporting framing, insulation and cavity fire barriers.

Reinforced Bitumen Membranes: OBR Construction working with Sika Ltd | Hafod Eryri-Yr Wyddfa, Snowdon

Careful management of materials was essential given the remote location, co-ordinating which materials were brought up and down the mountain, ensuring minimum waste whilst adhering to strict weight limits imposed by the railway.

Roof Slating: M. Camilleri & Sons Roofing Ltd | Howell's School, Cardiff

This project involved re-roofing the 1,100 m2 slate roof. The new roof incorporates bands of Penrhyn Heather Blue and Vermont grey/green slates, which come in different sizes. These slates were part of the original design and needed to be replicated

Roof Tiling: Complete Waterproofing Services Ltd | Beechwood Central West, Basildon

One challenging house type includes three different roof pitches linked by a valley, hip, mono ridge, verge and raking verge, this required precise battening to ensure proper drainage, further complicated by vertical tiling on select properties.

Sheeting and Cladding: Lindner Prater Ltd | Everton FC

This project sets a new benchmark in stadia design. The standing seam roof system proved to be the ideal solution, capable of accommodating the roof’s subtle curvature. Its adjustable substructure enabled seamless alignment of panels across the two-directional curves.

Single Ply Roofing: Mariner Projects Ltd | Bottle Works, Guildford

The roof system, helps to deliver thermal insulation and an airtight construction, ultimately contributing to a reduced carbon footprint for the building – a principal characteristic of the design.

Small Scale Project < £25k: Karl Terry Roofing Contractors Ltd | Finsbury Circus Gazebo

Keymer used original samples as the template to produce the new tiles allowing for shrinkage in firing, The tiles took 18 months to make. The most complex part of the work was making sure that the tiles followed the concentric curve of the roof.

Solar Roofing: Marley Contract Services | Social Housing, North Ayrshire Council

This contractor is in year three of a five-year contract with North Ayrshire Council, installing 9,837 solar panels on various social housing properties. The chosen 335W SolarTiles provide free electricity to tenants, helping to alleviate fuel poverty in a region with one of the highest levels in Scotland.

Thanks to our sponsors of the UK Roofing Awards 2025